PRODUCT APPLICATION:

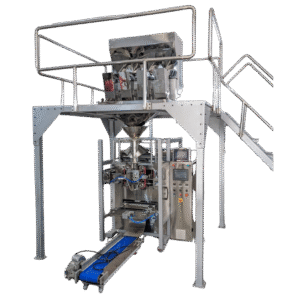

FEATURES:

| PLC | With 7-inch Color Touch Screen |

| Temperature Control | PID Temperature Controllers |

| Pneumatic | Festo / Comozzi |

| Electronic Sensor | Omron / Sick |

| Electronic Components | Schneider |

| Print Mark Sensor | Photo Electric Print Mark Teaching Sensor |

| Unwinding Unit | Motor Driven Unwinding Unit with Automatic Control |

| Packaging Operation | Pillow & Gusset Type Packaging Operation |

| Indication / Flushing | Tower Light Indication / Nitrogen Flushing |

| Safety | Emergency Stop |

| Covering | Stainless Steel Covering |

| Maintenance | Low Maintenance |

MULTI HEAD WEIGHER:

| Protection | IP-65 Protected |

| Cooling | Air Cooled |

| Bucket System | Timing Bucket with Error-Free Discharge Chute, 14 Bucket (Dimple Plated) Hopper Material Sensor |

| Structure | Stable 10 or 14 Bucket Structure |

| Weight Calculation | Best Weight Combinations Chosen by Scientific Computer |

| Precision | Correct Calculations by High-Precision Load Cell |

| Contact Parts | All Contact Parts Made of Stainless Steel to Maintain Neatness and Hygiene |

TECHNICAL SPECIFICATIONS:

| Sealing type / system | Center seal / 3 side seal with batch cutting (Pneumatic Intermittent Operated) |

| Filling System / Range | Multi head weigh filler / 5gm -1 Kg |

| Pulling System | Servo/ Vector Drive |

| Machine Speed | 30-80/Min. (Depending upon Pack Size) |

| Heaters | 250 watt 2 pcs./ 350 watt – 2 pcs |

| Laminate | Heat sealable laminate film. Core Dia-75mm/Max Outer Dia 350mm |

| Optional Attachments | Bucket Conveyor, Out feed Conveyor, Ink Jet / TTO Printer |

| Power/Power Consumption | 415 Volt / 50 Hz / 6.5 KW |

| Machine Dimension / Weight | 3500(L) X 3500(W) X 3650 (H)mm / 1900 Kg Approx |

| Air Compressor | 8 CFM |

Reviews

There are no reviews yet.