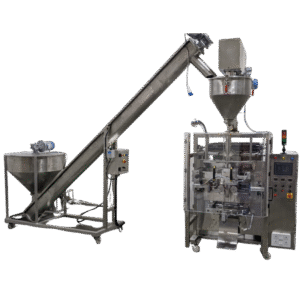

PRODUCT APPLICATION:

PRODUCT FEEDING & WEIGHING PROCESS:

| ► The product feeding system consists of a set of vibratory trays (front & rear) feeds the product into the pan. A uniform layer is maintained by synchronizing the feeding from the rear and front vibrators to enable accurate weighing. |

| ► The receiving pan is mounted at a strain gauge called load cell, which provides a signal. The signal, though small, is amplified and transmitted to process control electronics. |

| ► In the process control, the control panel receives the signal from the load cell and, after processing the same, compares the data with the pre-set values and gives signal to the vibrators. |

| ► The control panel has two set values – Bulk weight value and Target set weight value. The bulk weight is always set less than the target value, normally 80 to 95% depending upon product characteristics. Initially both vibrators run in Coarse mode, and when the bulk weight is achieved, the vibrators enter Fine mode; the coarse trap shutter closes and stops coarse feeding. |

| ► The final set weight is achieved by fine feeding through the fine tray to ensure accurate weighing. |

| ► On achieving the preset weight, the pan opens and dumps the product. |

Reviews

There are no reviews yet.